ROUNDTRACER Flash- MITUTOYO | JSR GROUP

ROUNDTRACER Flash- MITUTOYO Measurement and Analysis made easy | JSR GROUP

|

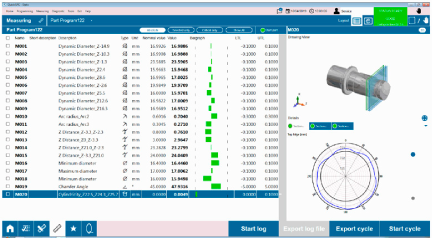

APPLICATION EXAMPLE 9x Dynamic Diameters 2x Arc Radii 4x Axial Distances 3x Groove Diameters 1x Cylindricity 1x Chamfer Angle MEASURING CYCLE TIME: 5.6 seconds! |

|

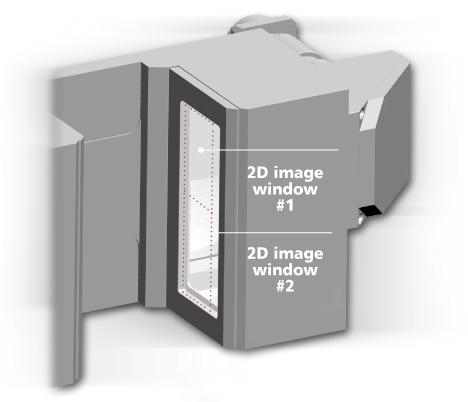

Roundtracer Flash is an optical measuring unit based on side-by-side 2D image architecture. |

|

FAST

With the absence of Z-axis motion the optical acquisition of the complete part - which consumes time on other systems - is

performed almost instantaneously on the Roundtracer Flash.

Therefore its cycle time is impressively fast. For example, it executes 100 static measurements in just 2 seconds irrespective of how

the measurement sections are distributed along the shaft length!

DURABLE

Fixed position sensors mean there is no mechanical stress.

The metrological performance of the Roundtracer Flash is consistent and stable over millions of cycles. There are also minimal

maintenance requirements.

| AUTOMOTIVE | ELECTRONICS | AEROSPACE | FASTENERS | MEDICAL |

|

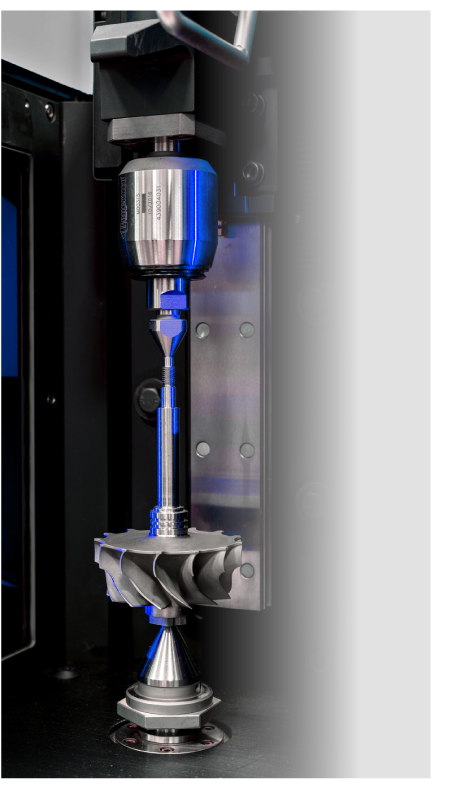

T U R BO CH A R G E R S

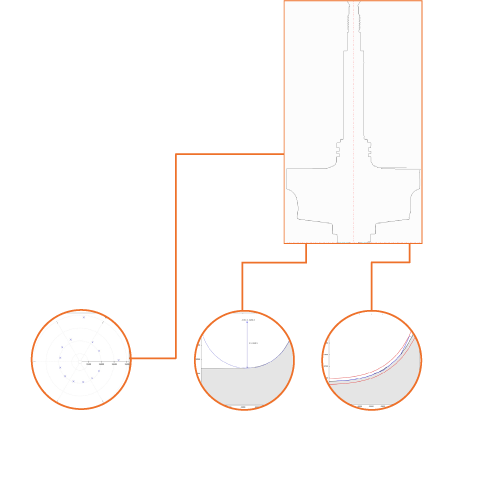

In fact, the Roundtracer Flash acquires the entire part profile into a single 2D image, which enables it to achieve the maximum acquisition accuracy of the blade profile and a superior measuring speed at the same time. A Roundtracer Flash is normally 2 times faster than traditional linear scanning solutions.

|